A Laser Dust-Free Working Table for Laser Cutting Head Glass Changing is a specialized accessory designed to maintain cleanliness and precision during maintenance of fiber laser welders or cutters — particularly when replacing protective lenses (glass) in the laser head. Here's a breakdown of its suitability and where it makes a real difference:

✅ High Suitability For:

Precision Laser Maintenance Environments

Ideal for workshops or facilities where laser cutting/welding optics are regularly maintained.

Provides a controlled, dust-free environment that protects delicate optics from contamination during lens changes.

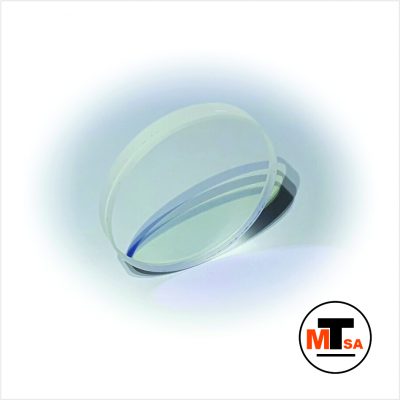

Protecting Optical Components

Laser lenses (focusing/protective) are highly sensitive to dust, oil, and moisture, which can cause:

Beam distortion

Reduced cutting/welding quality

Damage to the lens or head

A dust-free table extends the life of optical components and maintains machine performance.

High-Power Fiber Laser Systems (e.g., 1500W–6000W)

These systems require very clean optics to operate efficiently.

Suitable in professional setups using brands like Raytools, WSX, Precitec, or MORN, where optics are frequently serviced.

Workshop Standardization

Adds a level of professionalism and consistency to the maintenance process, especially in ISO-certified or production-critical environments.

|